The meat product can be dried alternately between cold air (10°C) and hot air (40-60°C). The internal fatty meat tastes better after drying. However, the cold-air drying time should not be too long because the surface of the sausage is prone to generate water.

1.Stage 1: constant rate of drying

It lasts for 5-6 hours, and the temperature quickly rose to 60-65 degrees within 2 hours after the sausage was loaded into the roasting room. The purpose is to make the inside and outside of the fresh sausage reach the same temperature within two hours. The heating process is also the fermentation process of the seasoning and meat. It can prevent the meat from changing its color and taste. After the warm-up time, adjusting the temperature to 45-50 degrees. At this stage, the surface water has been evaporated, and the color has changed from off-white to light red. This stage is the color changing period

2.Stage 2: deceleration drying phase

It last for 15-18 hours, which is not only the color fixing period, but also the shrinking and setting period.

3.Stage 3: colorfixingperiod

The temperature is controlled at 52-54 degrees for 4-6 hours, the sausage gradually turns from light red to bright red, and the casing begins to shrink.

4.Stage 4: shrinkage & setting period

The shrinking and setting period lasts for 11-12 hours. During this period, the water content inside the sausage continues to decrease, the sausage shrinks significantly, and the appearance appears uneven. The final drying humidity of the sausage is controlled at about 17%.

5.Stage 5: configuration and energy consumption:

7p drying room size is 4.2×2.2×2.6m

Each batch can dry 500-600 kg of sausages

Hourly power consumption is less than 6 degrees

If the drying time is 50 hours, the drying cost per catty of sausage is: 6×50/1000=0.3 kilowatt of electricity

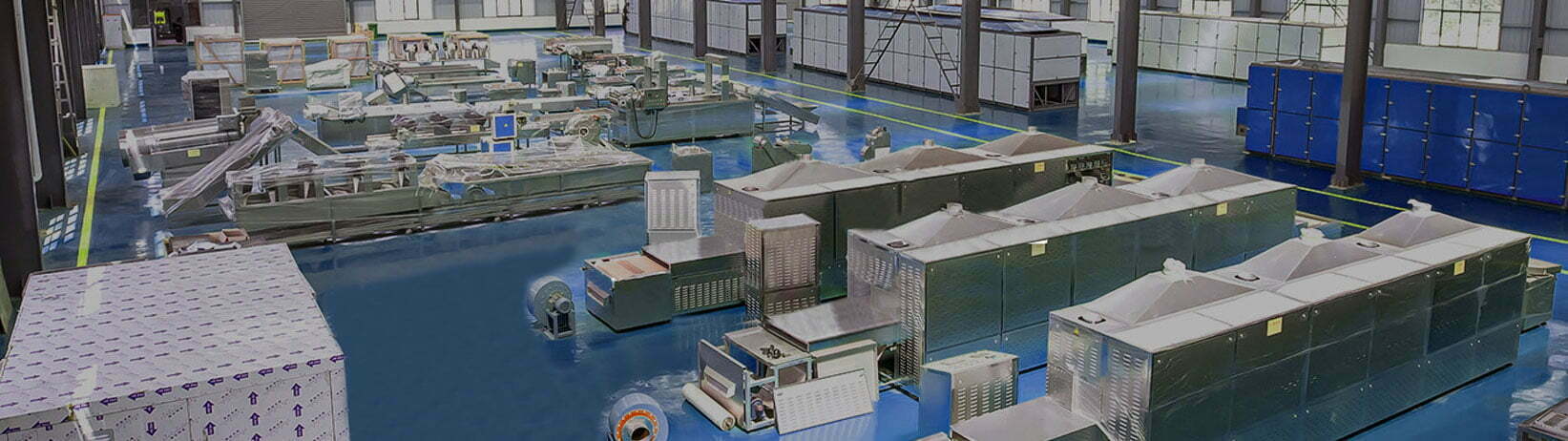

Schematic diagram of the working principle of air-energy drying equipment for bacon

Integral side air supply

Integral upper air supply

Integral rear air supply

Machine components:

1.Integrated machine with lateral air supply : it controls the start and stop bottom of the drying room, and controls the temperature, humidity and dehumidification time of the drying room. It also provides heat energy for drying materials.

2.Warehouse with polyurethane sandwich board: it provides heat preservation for materials in the drying room.

3.Fan wall: it provides wind energy for the materials to bring out the moisture in the materials, and it can bring out the heat energy in the mainframe to make the drying room heat up or cool down.

4.Air guiding wall: it guides the wind of the fan wall to the front end, so that the air volume before and after the drying room is consistent, which achieves the purpose of uniform drying.