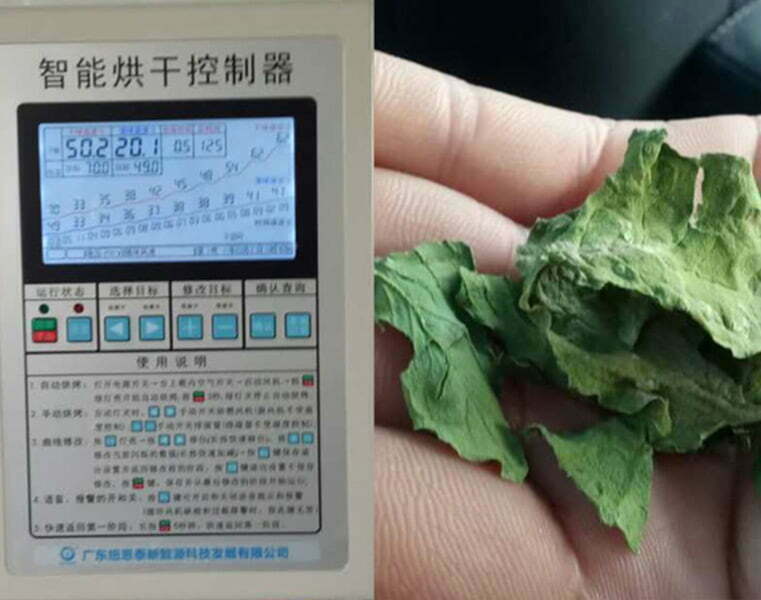

The mint leaf drying base in Anhui province uses a Shuntec heat pump drying equipment unit to solve the problem of mint leaf drying process. It uses a set of 3-hp drying equipment unit with a polyurethane drying room of 15 square meters for operation. After the user’s actual measurement, the entire drying process of peppermint leaf generally needs 12-15 hours, with the temperature controlled at 50-60°C. It poses a great challenge to the fan, which requires a high-temperature circulating fan machine.

The maximum temperature of the drying room is not less than 75℃. If you want to directly dried the mint leaf in a house build by bricks, you need to paste the insulation board (extruded board, asbestos board or benzene board) on the inner wall. By using Shuntec heat pump drying, you can achieve the best temperature for drying. Meanwhile, the finished product dryness, the color, fragrance, and the quality of the dried peppermint leaf made by Shuntec are very good, which makes the users very satisfied with Shuntec dryers.