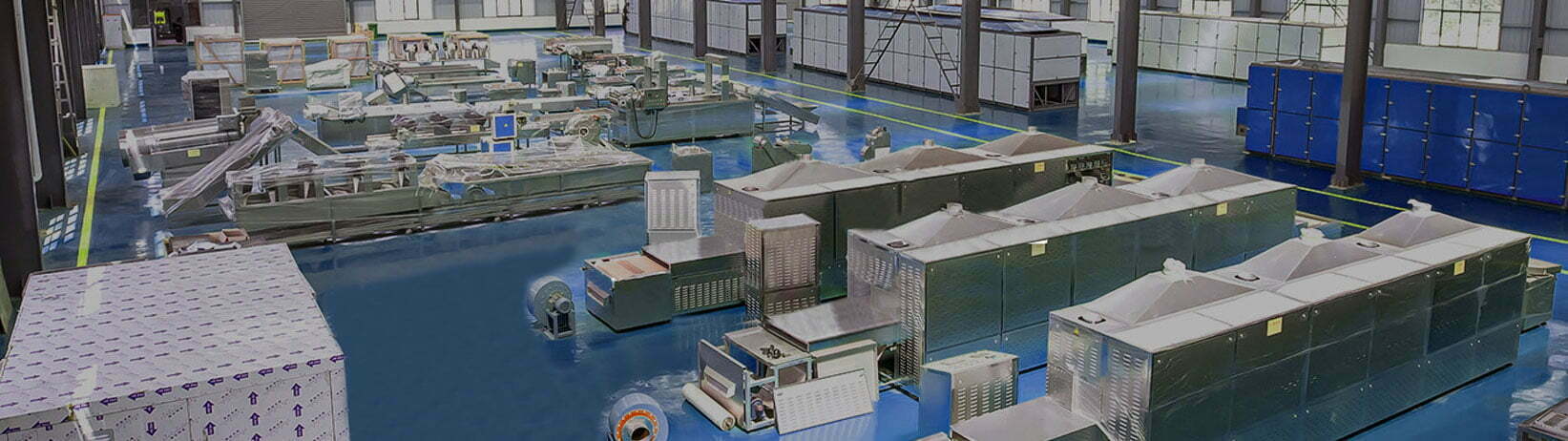

Integrated Machine for Condensation and Dehumidification

Product Description

Model:NE-DH020Z-U/ NE-DH070Z-U/ NE-DH100F-U/ NE-DH150Z-U1/ NE-DH250Z-U1

Power: 3P/7P/10P/15P/25P

Control screen: 7-inch control screen, intelligent control by computer

Machine features: it will not be influenced by ambient temperature, dehumidification effect is very strong. It only consumes a small amount of electricity to absorb a lot of heat in the air, and the power consumption is only 1/3~1/4 of electric heating, which can save about 75% of operating costs.

Application field: it mainly used for drying wolfberry, sausage, preserved meat, almond, fungus, red jujube, golden chrysanthemum, figs,etc.