Brief introduction to the principle of air energy fungus dryer

Shuntec air energy heat pump dryer special for fungus is the latest generation of environmental friendly and energy-saving products. The unit is based on the principle of reverse Carnot cycle and air energy heat pump. It uses electricity to drive the system, and utilize high temperature refrigerant to do work, meanwhile, it exchange the heat to absorbs energy in the air and directly outputs high-temperature hot air, that is 1 part of electric energy input could obtain 3~5 parts of heat for fungus drying. It is efficient and energy-saving, and the unit system works without pollution and zero emissions, which complies with environmental protection standards.

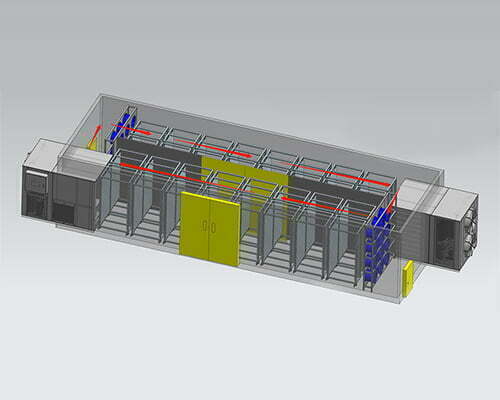

Schematic diagram of working principle of fungus air energy drying equipment

Integral side air supply

Integral upper air supply

Integral rear air supply

Machine components:

1.Rear/upper/sideair supply integrated machine: controls the start and stop of the drying room; controls the temperature, humidity and dehumidification time of the drying room; provides heat energy for material drying.

2.Polyurethane sandwich board warehouse: provides heat preservation for drying room materials.

3.Fan wall: Provides wind energy for the drying room materials to bring out the moisture in the materials; brings out the heat energy in the host to make the drying room heat up or cool down.

4.Air guide wall: guides the wind of the fan wall to the front end, so that the air volume before and after the drying room is consistent, and achieves the purpose of uniform drying of materials.

Mushroom drying process

1、Materials to be dried:Generally speaking, it is more suitable for picking shiitake mushrooms that are not more than eighth ripe,after picking, the mushrooms are classified into grades,arrange the classified shiitake mushrooms evenly in the material drying tray,the cap is facing up when placed,be careful not to overlap repeatedly when the stalk is facing down;

2、Control of drying temperature:The temperature in the drying room is raised to 55 degrees in advance to put the mushrooms in the drying room,the pre-drying temperature should not be too high,Generally drying at 55-58 degrees for about 6 hours,dry for about 12 hours between 60-65 degrees,the temperature of the last stage is controlled above 70 degrees and dried for about 2-4 hours,the specific time needs to be set according to your own process requirements.

3、Drying quality inspection:The whole drying process takes about 20-22 hours,when the time is up, you can open the drying room to test the dryness of the mushrooms,press the junction between the cap and the stalk with your hand during inspection,If there are only traces, it means that the drying is qualified;If the hand feels soft and the gills will feel soft when pressed, you need to continue drying

Tips:

Characteristics of qualified shiitake mushrooms after drying:It has the unique special fragrance of shiitake mushrooms, the gills are yellow, intact, and not inverted,The final moisture content of shiitake mushrooms does not exceed 13%,Shiitake mushrooms should keep their original shape, round and flat caps, and keep their natural color!