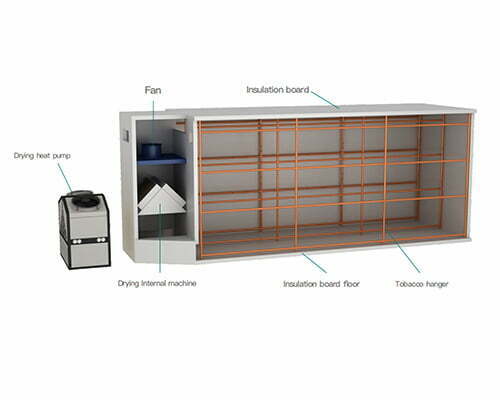

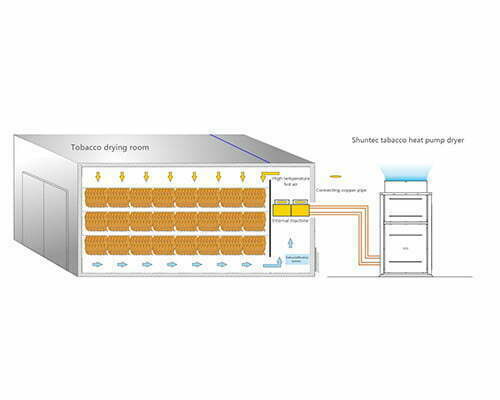

Machine Components:

1.Indoor unit: control the start and stop of the drying room, control the temperature, humidity, and dehumidification time of the drying room

2.Outdoor unit: absorb the heat of outdoor air and become isothermal and pressure gas to circulate again

According to the national three-stage tobacco leaf curing process standard for flue-cured tobacco, combined with the working principle of the steam absorption heat pump system, Shuntec Group has launched a tobacco leaf drying process standard with Shuntec characteristics after repeated experiments and demonstrations with the tobacco leaf curing process experts. The whole drying process is divided into three stages: yellowing period, color fixing period, and dry tendon period. The use of Shuntec heat pump dryers for flue-cured tobacco is environmentally friendly, safe, and energy-saving. At the same time, the temperature and humidity control during the flue-curing process is very stable, which improves the quality of tobacco leaves and brings greater economic benefits.

Yellowing period

The starting temperature is 32 degrees, and the temperature is increased by 1 ℃ per hour to 35-36 ℃ (maintain the temperature difference between dry and wet 1-2 ℃), and the temperature is stabilized until the tobacco leaves are soft and collapsed (generally, the lower leaves need 10-15 hours, and the middle leaves 15 -20 hours, upper leaves 20-25 hours); then increase the temperature to 38-39°C, keep the wet bulb temperature at 36-37°C, and stabilize the temperature until the tobacco leaves turn yellow and reach yellow flakes and green ribs, and then heat up to 42°C, The wet-bulb temperature is within 37°C, and the temperature is stabilized for 10-15 hours to dehumidify in advance, and then the temperature is increased to the color fixation period. (The yellowing time is generally 60-72 hours for the lower leaves, 48-60 hours for the middle leaves, and 36-48 hours for the upper leaves.)

Fixation period

After the tobacco leaves reach yellow flakes and green ribs, and the leaves become soft, the temperature of the drying room is raised to 45-48℃ at a rate of 1℃ every 2-3 hours, and the humidity control is wet bulb temperature is 37-39℃. When tobacco leaves turned into yellow slices, yellow tendons, and small rolls, keep the temperature steady until all the tobacco tendons turn yellow; then heat to 50-52°C, keep the wet bulb temperature at 38-40°C, and dry until the tobacco leaves are tipped into a large roll, heat up to 54-55°C (wet bulb 38-40°C) for more than 12 hours and then increase the temperature to reduce the color difference between the front and back of the tobacco leaf and promote the tobacco leaf curing; Humidity shall prevail, and the wet-bulb temperature shall not exceed the requirements during the whole process.

For tobacco leaves with large differences in quality of fresh tobacco leaves, it is required to stretch the drying time at the temperature of 45-48°C as long as possible and then heat up after the tobacco tendons are completely yellow, so as to reduce the production of green tendon tobacco after roasting.

Dry tendon period

After the tobacco leaves meet the color fixation requirements, quickly raise the dry bulb temperature to above 60°C, the highest temperature cannot exceed 68°C, the highest wet-bulb temperature does not exceed 43 °C, generally, 39-42 °C, drying until the tobacco ribs are completely dry, generally 30-40 Hour.