Drying of Herbal medicine

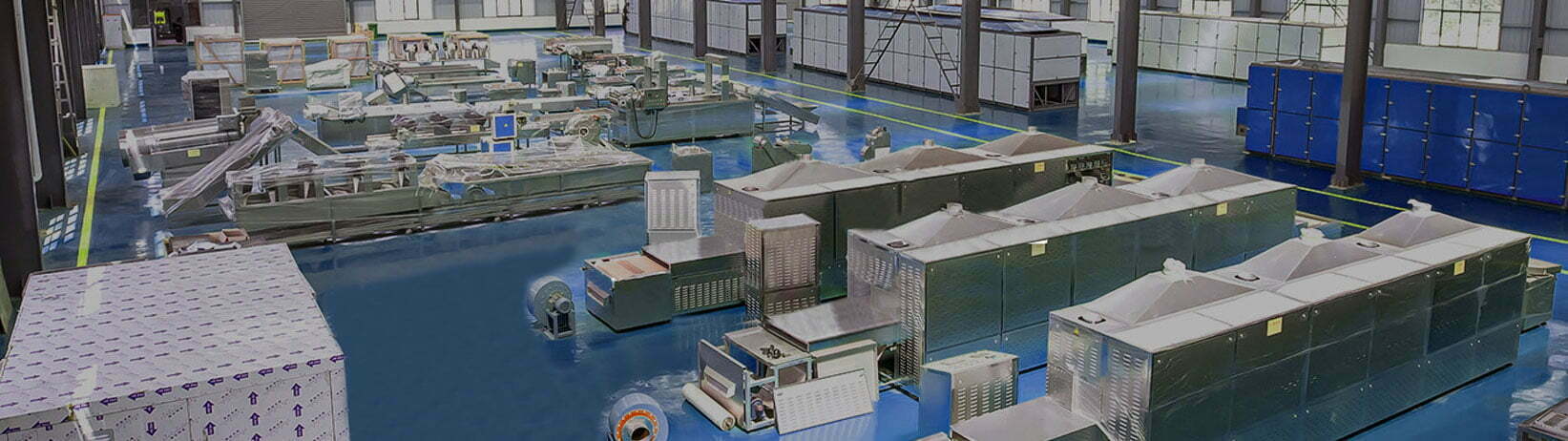

Product Description

Model: AHRZ 070S-ZD/AHRZ 140S-ZD/AHRZ 070S-B-ZD /AHRZ 140S-B-ZD /AHRZ 070S-U-ZD /AHRZ 140S-U-ZD

Power: 7P/14P

Type: Chinese herbal medicine drying

Structure:Integral and low-temperature type with circulating side air supply

Integral and low-temperature type with circulating rear air supply

Integral and low-temperature type with circulating upper air supply

Control screen: 7-inch control screen, computer intelligent control

Machine features: Efficient,Reliable,High Quality and Constant Processing

Application field: it mainly used for drying rhizomatous, flaky or vine-like type herbs materials, such as ginseng slices, astragalus, platycodon, Alisma, honeysuckle, safflower, chrysanthemum, angelica, citrus aurantium, cinnamon, hyssop, polygonatum, asparagus, yam, Peppermint, wood incense, bergamot, tangerine peel, barley seed, cassia seed, schisandra, rose, safflower, dogwood, melon, magnolia, eucommia, dandelion, plantain, mint, ageratum, perilla, gastrodia, dihuang, Isatis root, maca, white peony root, salvia miltiorrhiza, Chuanqiong, pinellia, yam, panax notoginseng, yam, ginger, kudzu root