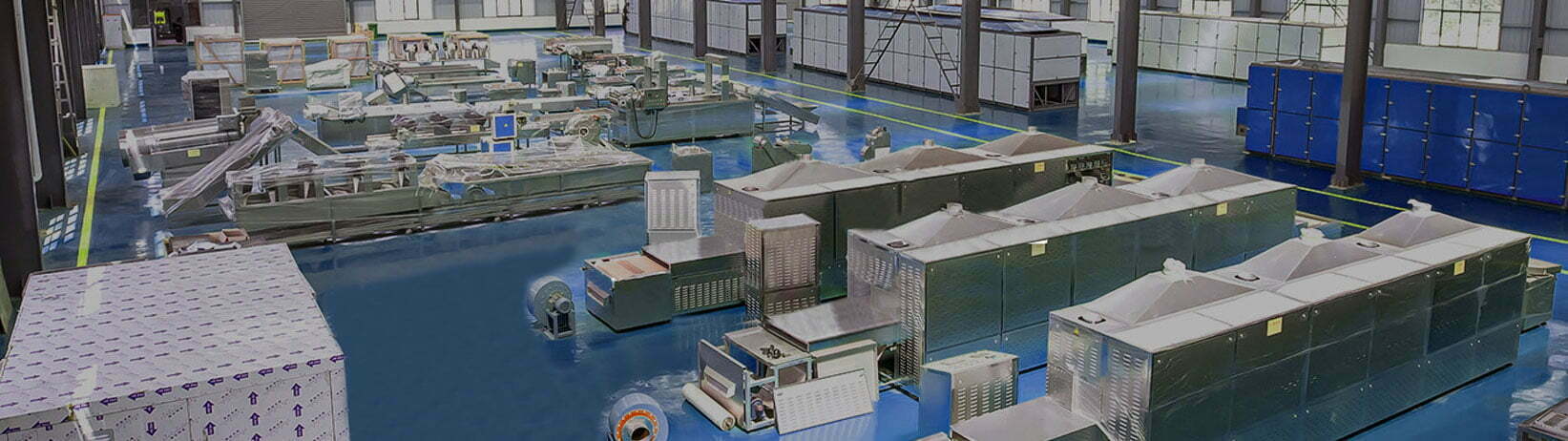

Split heat pump drying unit

Product Description

Model: Normal temperature type 060S-U/120S-U

Low temperature type 070S-U-Z/140S-U-Z

Power: 6P/12P/7P/14P

Type: Opening type

Structure: Split type, the equipment unit has no dehumidification function, it only drying the materials in the drying room, which connects to an external dehumidifier fan for drying the material.

Machine features: Heat up fast, High energy efficiency, low cost, flexible installation, Good drying effect.

Application field: it mainly used for drying flowers and leaves, Fruits, Meat and poultry, etc.

The normal temperature type is suitable for the environment above 0℃, the low temperature type is suitable for the environment above -10℃.

-1.jpg)

-1.jpg)

2.jpg)