Integrated rear air Heat Pump Dryer

Product Description

Drying weight: 350-600 kg/500-750 kg/900-1100 kg

Drying room specifications: 18-23 cubic meters/25-30 cubic meters/45-50 cubic meters

The way of wind out : rear air supply and upper return air

Control screen: a 7-inch control screen, computer intelligent control

Machine features: safety, energy saving, environmental protection, intelligence

Application field:

5P is mainly used for hanging materials such as flowers and leaves, rhizomes, industrial products, etc.

7P is mainly used for hanging materials such as sausages, bacon, rice noodles, yuba, and agricultural products

14P is mainly used in agricultural products such as Chinese medicinal materials, flowers, and leaves, rhizomes, goji berries, peppers, etc.

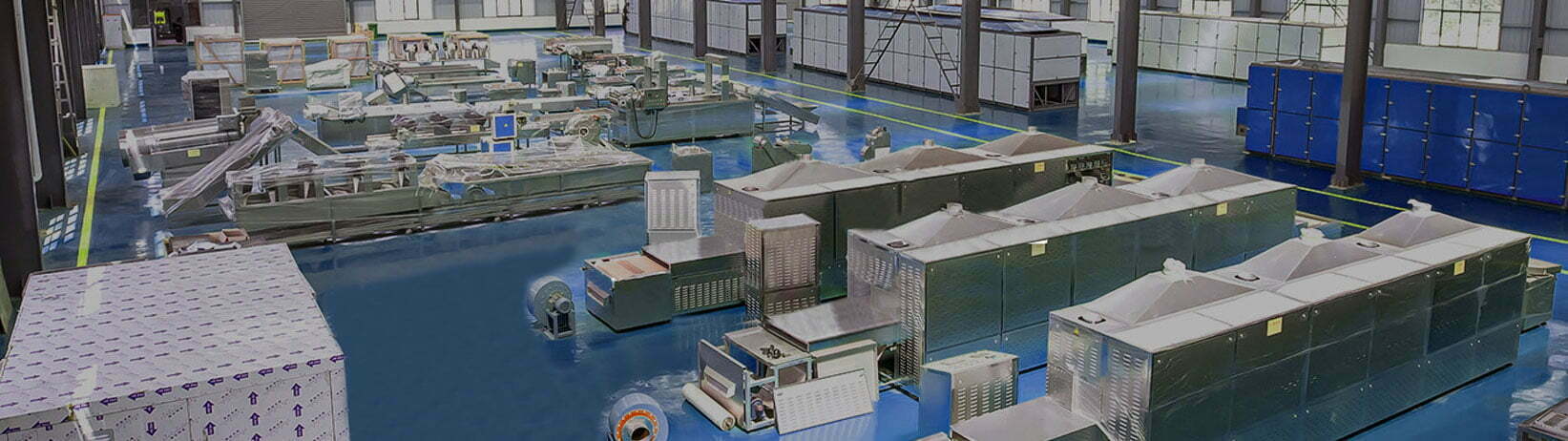

Integrated Heat Pump Dryer with Lateral Supply

Product Description

Drying weight: 500-700 kg/700-900 kg/1000-1500 kg/2000-2500 kg

Drying room size: 14-28 cubic meters/18-22 cubic meters/25-30 cubic meters/40-50 cubic meters

The way of wind out: lateral air supply

Control screen: 7-inch control screen, intelligent control by computer

Machine features: safety, energy saving, environmental protection, working efficiency

Application field: it could be used for drying (1) tiled materials such as flowers and leaves, rhizomes, industrial products, etc.; (2) agricultural products such as Chinese herbal medicine, wolfberries, peppers, etc.

Integrated Heat Pump Dryer with Underfloor Air Supply

Product Description

Drying weight: 500-750 kg/1000-1250 kg

Drying room: 25-30 cubic meters/45-50 cubic meters

The way of wind out: underfloor air supply and upper return air

Control screen: 7-inch control screen, intelligent control by computer

Machine features: safety, energy saving, environmental protection, working efficiency

Application field: it is mainly used for hanging materials such as wood, sausages, bacon, rice noodles, bean curd stick, and woods.