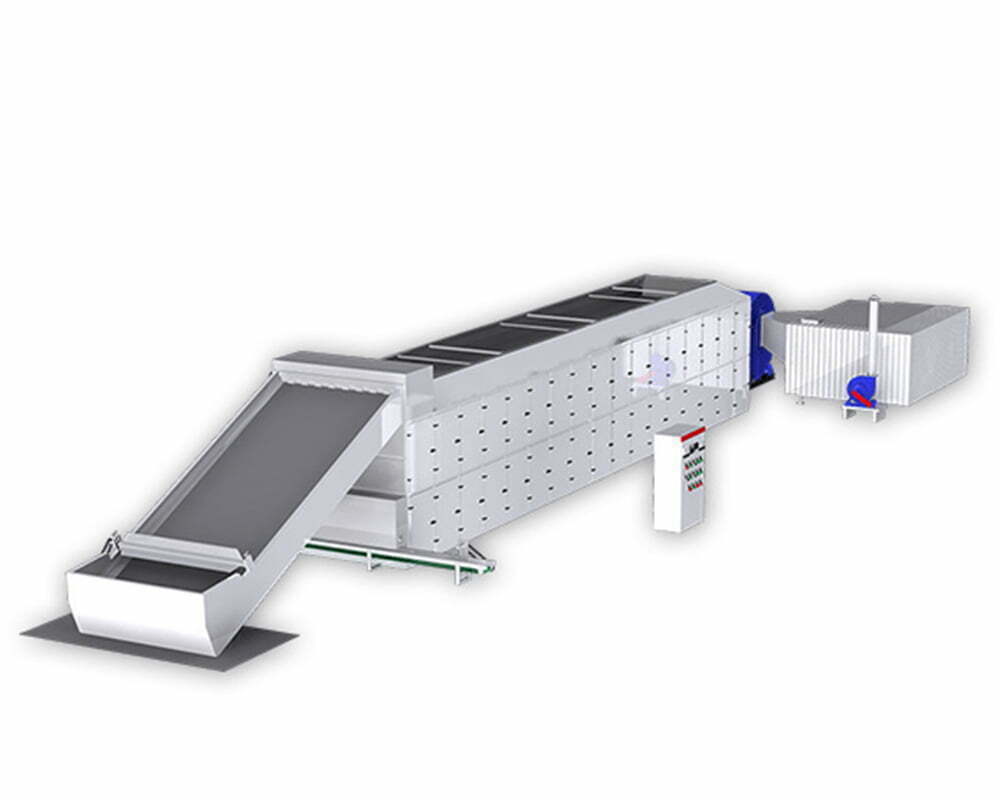

The core advantages of Shuntec air heat pump drying machine

1、Larger Quantities drying ,High drying efficiency,Low labor intensity,Continuous drying

2、The speed of the mesh belt can be adjusted to achieve the best drying effect

3、Flexible equipment configuration, mesh belt dryer can use mesh belt washing system and material cooling system

4、Most of the air in the mesh belt through-flow dryer is recycled, highly energy-saving

5、Large output: The chrysanthemum dryer adopts a multi-layer circulating dynamic drying mode, which can be batch dried for 24 hours.

6、High quality: the dried material has bright color, complete shape and moderate moisture, which is loved by users

7、Intelligent and accurate: The use of intelligent control system can ensure accurate control of temperature, duration, air volume and other parameters in the drying process.

8、Cost saving: The whole set of equipment can be completed by only one person, and the drying time is shortened, saving labor and time costs.

9、Clean and hygienic: The entire drying process is completed in a closed box and will not be polluted by the outside world.

10、Long life of the equipment: The overall operation speed of the dryer is very slow, and there are almost no vulnerable parts.