Intelligent integral heat pump drying system principle

Working principle of direct heating grain dryer(Combined with drying tower)

It adopts mixed flow approach for drying, the cleaned grains are fed to the dryer by the elevator. Grain flows continuously from top to bottom of the equipment by its own weight, which achieves tempering and drying in the flow process.

The hot air and the grain can flow in the same direction and flow in the opposite direction, which is called mixed flow. After adjusting the temperature of the heat pump dryer, the hot air will transfer heat and moisture to food when the hot air passes through the grain layer. After the hot air transfers heat to grains, the temperature will be increased, the grain is heated up, and water evaporates into the air and discharged as exhaust. If you could reasonably match the air volume of the induced draft fan, you could realize the control of various drying temperatures and air volume ratios. After adjusting the speed of the motor for discharging grain, the residence time of grains in the drying section can be controlled, and the dried hot food flows down to the tempering section. The temperature and water content of the inner and outer layers of the grain tend to be balanced after the tempering section, which could realize moisture uniformity of the whole batch of grain, and could achieve the purpose of high-quality, high-efficiency, energy-saving drying process.

Working principle diagram(Combined with drying tower)

Machine components:

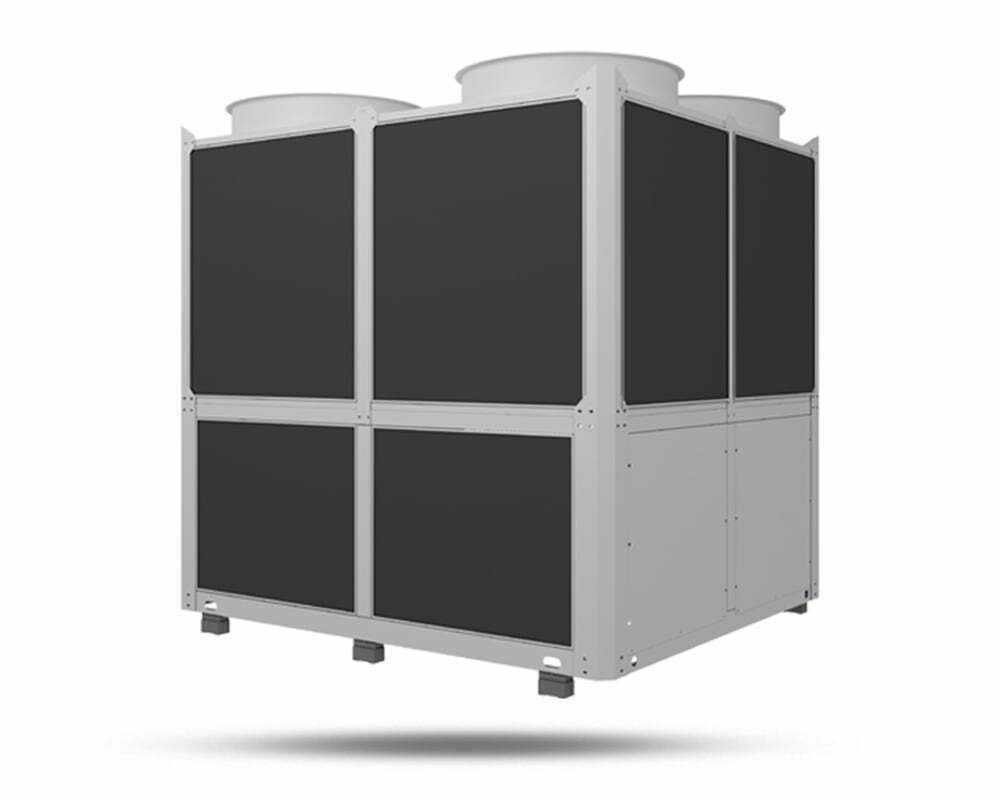

1.Heat pump drying mainframe:it mainly used for connecting the drying tower, the heat source is to absorb the air and then use it for compression, and then generate gas with high temperature and high pressure.

2.Drying tower:Grain dryer equipment is divided into heat source and drying tower, the drying tower transports our grain to the drying area, and then drying along with the belt and flow down. After the drying is completed, it will enter into grain discharge area for discharge

Working principle of direct heating grain dryer(Combined with mesh belt)

The mesh belt drying equipment uses hot air as the drying medium, the hot air generated by the air energy heat pump is sent to the drying box through a centrifugal fan to dry the material, the processed material is conveyed by multi-layer stainless steel mesh belt. After several times of multilayer cyclic flip in the drying box, the hot air is introduced into the dryer by the fan. The wind speed and wind pressure generated by the induced draft fan make the hot air fully and evenly released at the bottom of the dryer. As the lower pressure is greater than the upper pressure, the hot air moves upward and passes through the mesh belt and material layer from bottom to top, making the material fully contact with the hot air and the drying process could be finished layer by layer.

Working principle diagram(Combined with mesh belt)

Machine components:

The drying production processing line comprises a drying mainframe, a feed conveyor, a discharge conveyor, a direct heating heat pump and a hot air inlet. The drying mainframe comprises a box body, a frame arranged in the box body, a chain mesh conveyor installed on the frame and its driving unit. The box body is provided with a feed inlet, a discharge outlet and a hot air inlet, and the hot air inlet is arranged at the bottom of one end of the box body. The top of the box body is provided with a moisture outlet. The direct heating heat pump comprises a chassis, an evaporator installed at the upper part of the chassis and a condenser installed at the lower part of the chassis, it also include compressors and throttles respectively connecting the evaporator and both ends of the condenser. The top of the chassis is provided with several air inlets, each air inlet is equipped with an induced draft fan, the evaporator is located below the induced draft fan, and the air inlet fan is connected between the condenser and the hot air inlet.

1.integrated drying machine: it controls the start and stop bottom of the drying room, andcontrols the temperature, humidity and dehumidification time of the drying room. It alsoprovides heat energy for drying.

2.warehouse with polyurethane sandwich board:itprovides heat preservation for materials in the drying room.

3.centrifugal fan: it provides wind energy for thematerials andbrings out the moisture in the materials. It also brings out the heat energy in the mainframe to make the drying room heat up or cool down.

4.material conveyor belt: After the material has been putted onto the conveyor devices evenly, it will be transmitted to the mesh belt of the dryer.