Low-temperature Box Dryer for Sludge

Product Description

Model: ST-CSJ07WN-XT/ST-CSJ15WN-XT

Power: 7P/15P

Type: Sludge drying

Name:Low-temperature box dryer for sludge

Structure:Low-temperature drying

Machine features: Safe and stable, no explosion hazard, automatic adjustment, durable, zero emission, intelligent control, automatic dust removal, high energy efficiency

Application field: it mainly used for drying municipal sludge, industrial sludge, printing and dyeing sludge, pharmaceutical sludge, chemical sludge, leather sludge, electroplating sludge, circuit board sludge, metal sludge, wine sludge, paper sludge, coal Mud, etc..

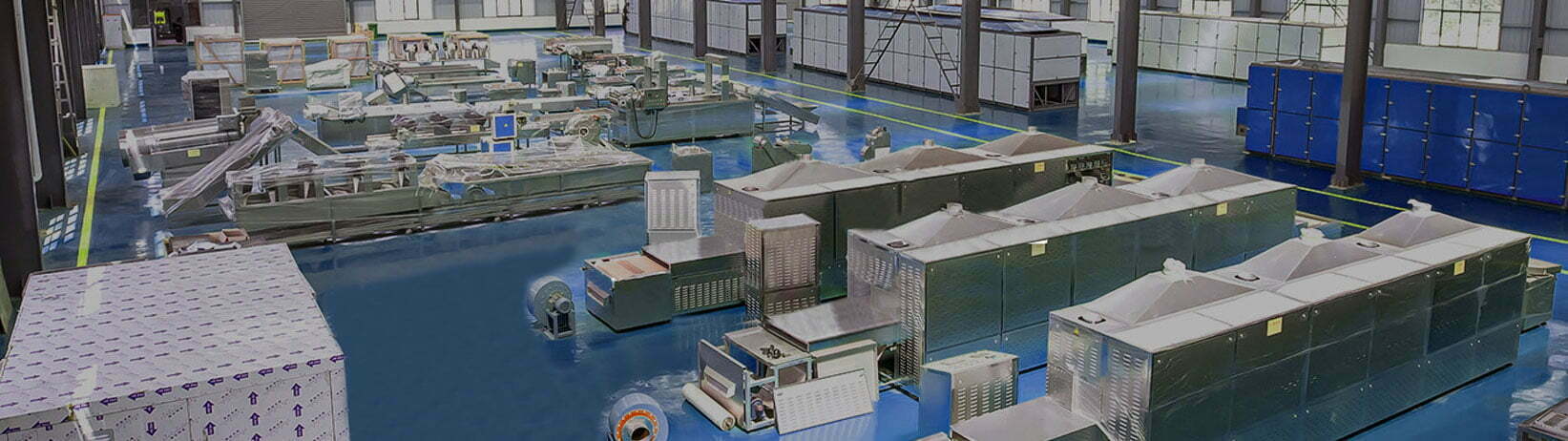

Automatic Production Line for Sludge Drying

Product Description

Model: ST-LSX-X series

Power: 15P/25P/40p/55p/105p/135p

Type: Sludge drying

Name:Automatic production line for sludge drying

Structure:Automatic production line

Machine features: Safe and stable, no explosion hazard, automatic adjustment, durable, zero emission, intelligent control, automatic dust removal, high energy efficiency

Application field: It mainly used for drying municipal sludge, industrial sludge, printing and dyeing sludge, pharmaceutical sludge, chemical sludge, leather sludge, electroplating sludge, circuit board sludge, metal sludge, wine sludge, paper sludge, coal Mud, etc..

Low-temperature Dryer for Sludge with Automatic Dust Removal Function

Product Description

Model: ST-LSX-MC series

Power: 15P/25P/40p/55p/105p/135p

Type: Sludge drying

Name: Low-temperature dryer for sludge with automatic dust removal function

Structure:Low-temperature dust removal structure

Machine features: Safe and stable, no explosion hazard, automatic adjustment, durable, zero emission, intelligent control, automatic dust removal, high energy efficiency

Application field: It mainly used for drying municipal sludge, industrial sludge, printing and dyeing sludge, pharmaceutical sludge, chemical sludge, leather sludge, electroplating sludge, circuit board sludge, metal sludge, wine sludge, paper sludge, coal Mud, etc..

Low-temperature Waste Heat Dryer for Sludge

Product Description

Model: ST-LSX-Y series

Power: 16P/30P/45p/60p/75p/90p/105p

Type: Sludge drying

Name:Low-temperature Waste Heat Dryer for Sludge

Structure:waste heat drying structure

Machine features: Safe and stable, no explosion hazard, automatic adjustment, durable, zero emission, intelligent control, automatic dust removal, high energy efficiency

Application field: It mainly used for drying municipal sludge, industrial sludge, printing and dyeing sludge, pharmaceutical sludge, chemical sludge, leather sludge, electroplating sludge, circuit board sludge, metal sludge, wine sludge, paper sludge, coal Mud and other drying reduction