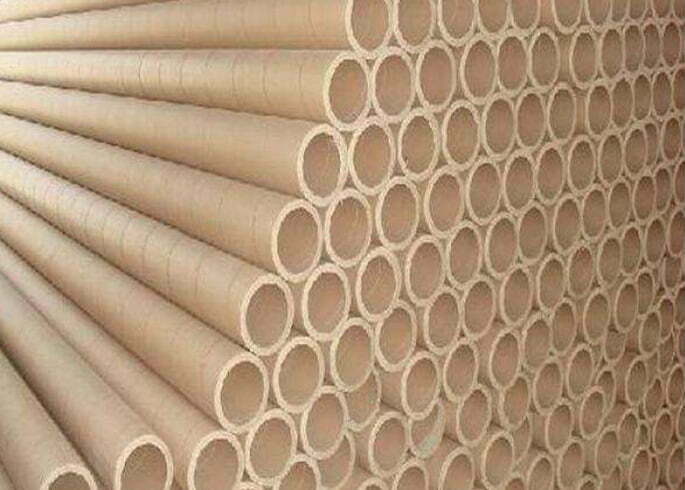

Process steps of firework paper tube processing

The preparation process of firecrackers is divided into 10 steps, including paper cutting and paper separation, paper rolling, mud bottoming, charging, bright beads, wire assembly, mud head, glue injection, rolling, braiding, and packaging. Among these steps, there are many processes that need to be dried, such as the paper baking in the previous process, the drying for the finished product, and some key sub-processes, such as the drying of Pyrotechnics and bright beads, the drying of the fuse, etc. .

Firework paper tube drying process

- Drying room should meet the following requirements

(1) When drying with water heating, the fixed quantity of a drying room should be less than or equal to 1000 kg, and the drying room temperature should be less than or equal to 60℃. When drying with hot air, the fixed quantity of a drying room should be less than or equal to 500 kg, and the temperature should be less than or equal to 50℃, meanwhile, measures should be taken to prevent the Pyrotechnics from generating dust, and the wind speed should be less than or equal to 0.5 meters per second.

(2) The drying room should be equipped with a temperature sensing alarm device to maintain uniform heating, and the heating rate of the drying room should be less than or equal to 30℃ per hour.

(3) The drying room should be equipped with dehumidification device and should dehumidify in time.

(4) The Pyrotechnics trays in the drying room should be steadily placed on the drying rack in layers.

(5) The stacking of Pyrotechnics in the drying room should comply with the regulations.

(6) Transport and evacuation passages should be left between the drying racks, with a width greater than or equal to 100 cm.

(7) The drying room should be managed by a staff, and no one should enter when heating and drying process of the Pyrotechnics is ongoing. the fixed number for each drying room is 2 people.

(8) The drying room should be kept clean, and no Pyrotechnics should be left on the radiator.

- For the finished products and semi-finished products with pyrotechnicss

(1) It should be carried out in a special place (e.g. drying yard or drying room).

(2) The requirements of each drying room, such as quota, quantitative, thermal energy selection, and drying method, shall be implemented in accordance with regulations.

(3) The lifting frame for the firework bombs should be framed. The height of the frame should exceed 1/2 of the diameter of the firework bombs. The projectile body (ball) should be placed in a single layer.

(4) the drying process of product should not be carried out in the same drying room with pyrotechnics product, and friction products should not be dried in the same drying room with other products.

(5) The temperature of the steam drying room is less than or equal to 75℃, and the temperature rise rate is less than or equal to 30℃ per hour, so rib-shaped radiators should not be used.

(6) the room temperature of hot-air drying room for finished products and semi-finished products with Pyrotechnicss is less than or equal to 60°C, and the wind speed is less than or equal to 1 meter per second. Dust removal equipment should be provided for circulating-air drying, and the dust removal equipment should be cleaned regularly.

(7) A temperature alarm device should be installed in the room, and the guarding staff should strictly control the rise and fall of the temperature. Any abnormal situation should be dealt with in time and reported to the person in charge of safety management.

(8) The dried finished products and semi-finished products with pyrotechnicss should be ventilated and dissipated. During the drying and heat dissipation process, it should not be turned over and collected, and should be collected when it is cooled to the room temperature.