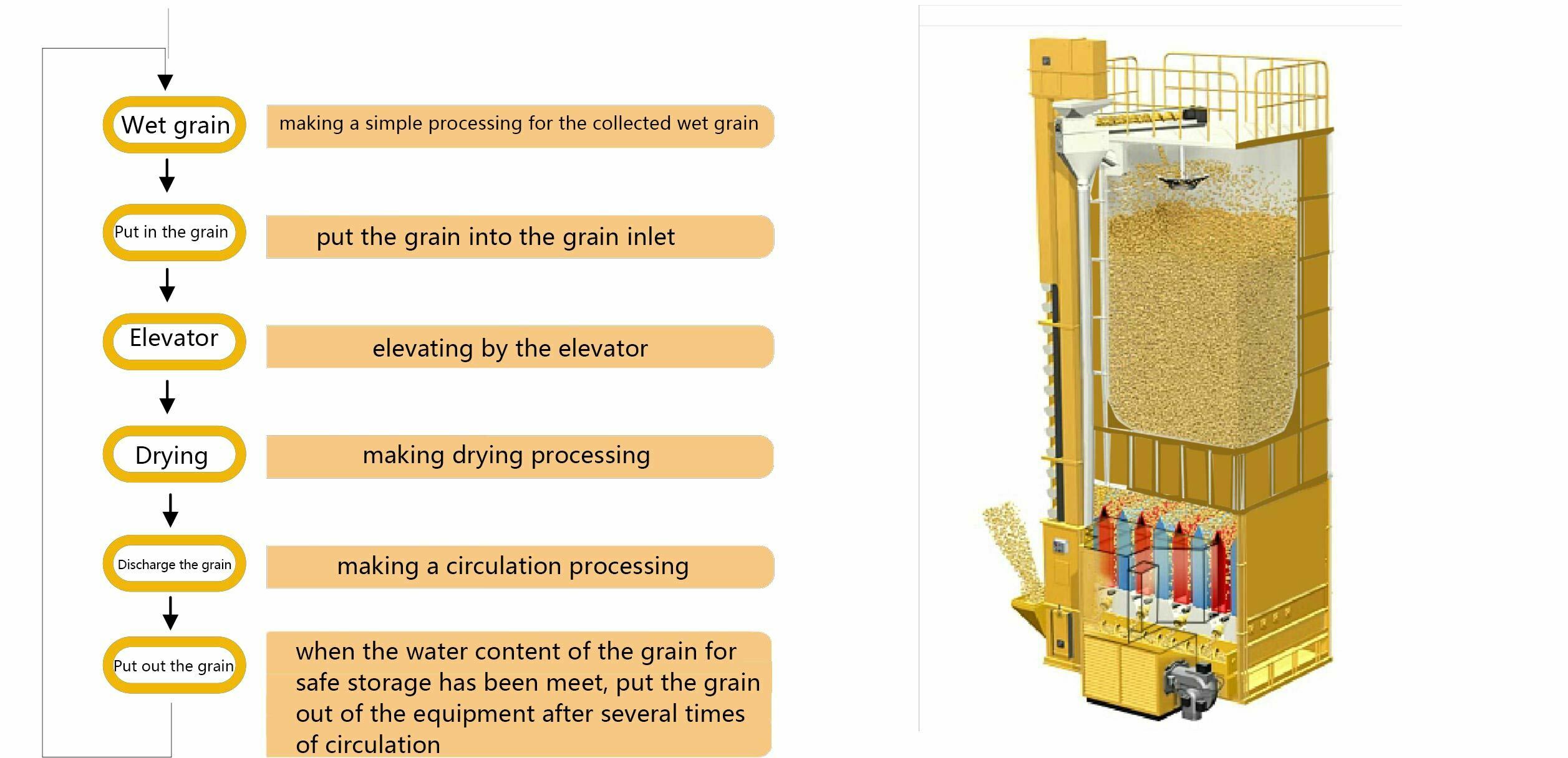

Integrated Grain Heat Pump Dryer

Product Description

Model: AHRZ 1450-U-ZD/AHRZ 2550-U-ZD

Power: 37P/50P

Type: Grain dryer

Structure: Integrated structure

The way of wind out: underfloor air supply

Control screen: 7-inch control screen, computer intelligent control

Machine features: Safe operation, high efficiency, energy saving, environmental protection, unattended, precise temperature control, high quality and worry-free

Application field: it is specially used for drying grains, coffee beans, wheat, corn, soybeans, etc.

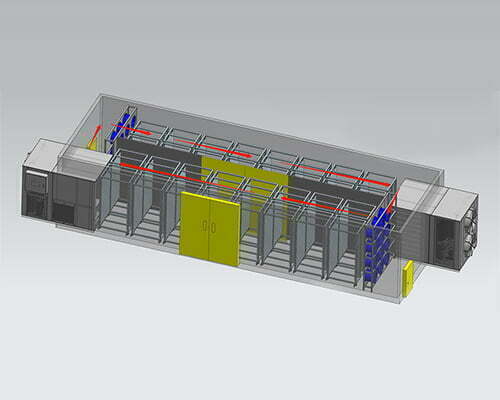

Heat Pump Dryer Special for Pet Feed

Product Description

Model: DL-RFX-3P/DL-RFG-3P/DL-RFS-6P/DL-RFS-12P

Power: 6P/12P

Type: Pet feed drying

Structure: Integrated structure

Control screen: 7-inch control screen, computer intelligent control

Machine features: It can simulate cold air which generated in winter weather conditions for drying, with high degree of automation. The production environment is very clean, and labor cost can save a lot.

Application field: it is suitable for drying all kinds of pet snacks: such as capelin fish, beef knee bone, duck neck, meat bones, meat cubes, steak slices, beef strips, duck strips, cheese bone wrapped meat, cowhide foam ring (molar ring) , Pet supplies, cowhide rolls, chicken/duck cowhide doughnuts, cowhide bones, molar sticks, chicken sticks, dog snacks, chicken pigskin sticks, dog chews, etc.

Integrated Coffee Heat Pump Dryer

Product Description

Model: AHRZ 1450-U-ZD/AHRZ 2550-U-ZD

Power:37P/50P

Type: Coffee beans drying

Structure: Integrated structure

The way of wind out: underfloor air supply

Control screen: 7-inch control screen, computer intelligent control

Machine features:Safe operation, high efficiency, energy saving, environmental protection, unattended, precise temperature control, high quality and worry-free;

Application field:it is used for drying coffee beans, grains, wheat, corn, soybeans, etc.