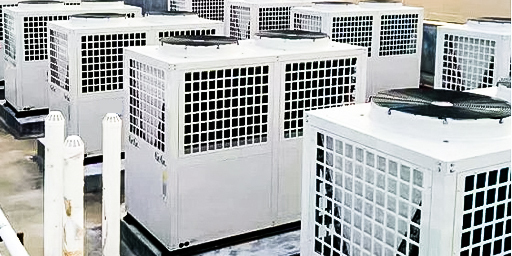

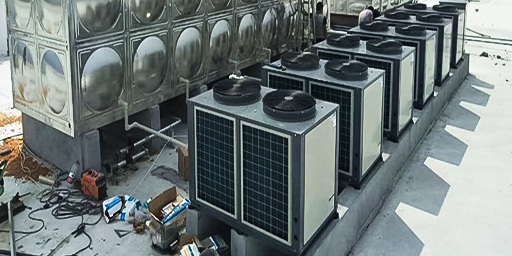

The air energy heat pump works according to the “reverse Carnot” principle. It works through the operation of the compressor system and absorbs the heat in the air to make hot water.

In summer, the air energy heat pump is used to cool, keeping the indoor temperature at around 20-24°C. During refrigeration, the liquid refrigerant vaporizes in the water heat exchanger, reducing the water temperature.

Efficient defrosting and short defrosting time. When used in severe winter, especially between -3°C and 5°C, at this time, the main unit of the air source heat pump is obviously frosted, and the impact of defrosting on the indoor temperature is a very troublesome problem.

To complete heating, an air-energy water heater must use a refrigerant as an intermediate medium to continuously absorb heat from the air.

Many greenhouse operators have begun to realize the advantages of air energy heat pumps in greenhouses. The use of heat pumps for greenhouse heating has become a “standard configuration.”

The air source heat pump is thicker than the air conditioner. The air source heat pump can withstand the working temperature of 60°C, but the air conditioner can only reach 40°C.

Pour the descaling agent of the air energy heat pump hot water system into the water storage bucket according to the ratio of 1:5-10, and circulate evenly. Turn on the main engine of the air energy heat pump, and circulate for 2-3 hours.

When the air energy heat pump is cooling in summer, the unit stops working when the water temperature is 0°C-10°C and starts working when the water temperature is higher than 15°C.

Any air energy heating system installed according to professional design and specifications must save electricity compared with ordinary electric heating! Due to differences in the installation location, house insulation effect, and ambient temperature, the energy-saving effect will also vary accordingly.

Air energy: air is not a kind of energy, the form of energy includes electric energy, heat energy, solar energy, and so on. Heat pump: A device that uses high-level energy to flow heat from a low-level heat source to a high-level heat source